ROLLS, COUNTERROLLS, ROLLING CYLINDERS, WHEELS FOR CRANE, PULLEY, ROPE WINDING DRUMS

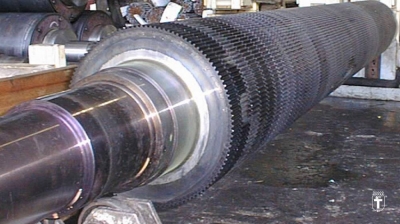

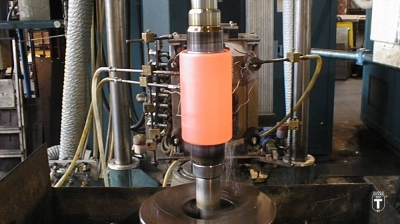

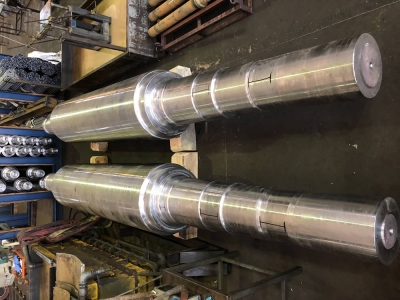

We carry out induction hardening of tables, pins and / or specific areas according to the design of rollers, back-up rollers, spindles, milling cylinders, various components used in leveling machines, machines for sheet metal processing, paper processing, plastic industry, textile, food sector, steel industry, precious metals etc.

Similarly, we perform the induction hardening of the grooves of wheels for overhead cranes and pulleys with and without edges, in the version with and without joints thanks to specific inductors made for large diameter cylindrical geometries. These wheels, together with cable winding drums are also induction hardened in the individual grooves, are components of large cranes frequently used in ports and cargo loading / unloading yards. They are products typically made of C45, 38NiCrMo4, 42CrMo4, 51CrMoV4, 56NiCrMoV7, 86CrMoV7, X40CrMoV5-1, X155CrMoV12.1 steel of various sizes, from small diameters to Diam.1000 mm with rollers of lengths up to 7 meters and 12 tons. Annually we work over 25000 pieces in series of tens / hundreds of pieces.

Depending on the materials and geometries, we can achieve significant hardness and depth of hardening thanks to selective equipment in low and medium frequency, reaching, for certain requests, even depths higher than 20 mm. To reduce any tension and deformation we are equipped with large furnaces dedicated to tempering and, for the rollers, straightening systems for restoring straightness.

Similarly, we perform the induction hardening of the grooves of wheels for overhead cranes and pulleys with and without edges, in the version with and without joints thanks to specific inductors made for large diameter cylindrical geometries. These wheels, together with cable winding drums are also induction hardened in the individual grooves, are components of large cranes frequently used in ports and cargo loading / unloading yards. They are products typically made of C45, 38NiCrMo4, 42CrMo4, 51CrMoV4, 56NiCrMoV7, 86CrMoV7, X40CrMoV5-1, X155CrMoV12.1 steel of various sizes, from small diameters to Diam.1000 mm with rollers of lengths up to 7 meters and 12 tons. Annually we work over 25000 pieces in series of tens / hundreds of pieces.

Depending on the materials and geometries, we can achieve significant hardness and depth of hardening thanks to selective equipment in low and medium frequency, reaching, for certain requests, even depths higher than 20 mm. To reduce any tension and deformation we are equipped with large furnaces dedicated to tempering and, for the rollers, straightening systems for restoring straightness.